In the realm of industrial work, accessing high places has always posed significant challenges and risks. Traditional methods such as scaffolding or cherry pickers are not only costly but can also be time-consuming and cumbersome. Rope access, however, has emerged as a revolutionary technique, offering a safe, efficient, and cost-effective solution for working at heights. This article delves into the advantages of rope access, covering safety, efficiency, versatility, and cost-effectiveness, providing a comprehensive overview for those considering this innovative method.

1. Safety: The Cornerstone of Rope Access

When it comes to working at heights, safety is paramount. Rope access systems are designed with multiple layers of safety, making them one of the safest methods for accessing difficult-to-reach areas.

- Training and Certification: Rope access technicians undergo rigorous training and must be certified by recognized bodies such as IRATA training (Industrial Rope Access Trade Association) or SPRAT (Society of Professional Rope Access Technicians). This training includes both theoretical knowledge and practical skills, ensuring that technicians are well-prepared to handle various situations safely.

- Redundancy Systems: One of the key features of rope access is its redundancy. Systems are designed with multiple backup lines, so if one fails, others are in place to ensure the technician’s safety. This redundancy significantly reduces the risk of accidents.

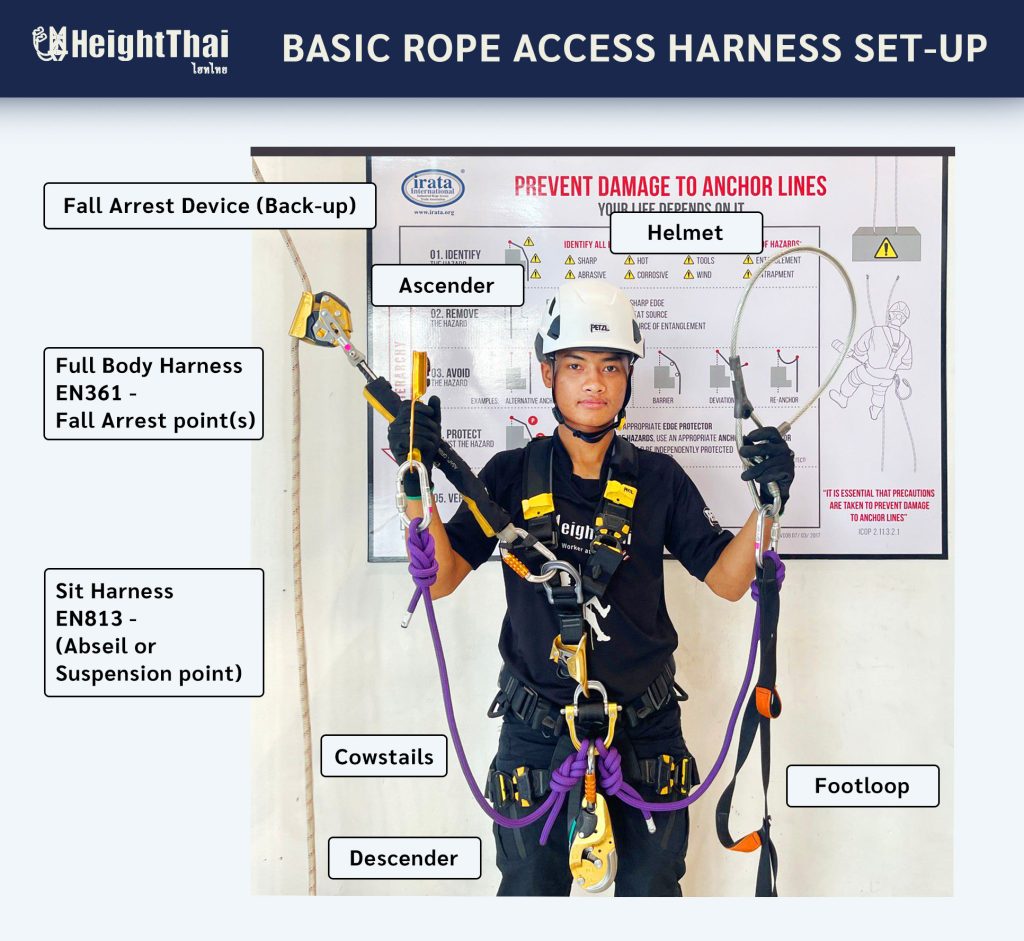

- Minimal Equipment Failure: Rope access equipment is subject to strict safety standards and regular maintenance. This includes harnesses, ropes, descenders, and karabiners, all of which are inspected regularly to ensure they meet safety requirements.

- Lower Risk of Falls: Traditional methods often involve the risk of falls from heights, but rope access minimizes this risk. Techniques such as double rope systems and the use of personal protective equipment (PPE) ensure that technicians are securely anchored at all times.

2. Efficiency: Speed and Flexibility in Accessing Difficult Areas

Rope access is not just safe; it is also incredibly efficient. Its flexibility and speed make it a preferred choice for many industries.

- Rapid Deployment: Unlike scaffolding or cranes, which require extensive setup and dismantling, rope access systems can be deployed quickly. This efficiency reduces downtime and increases productivity, making it ideal for projects with tight schedules.

- Access to Complex Structures: Rope access can reach areas that are otherwise inaccessible, such as the sides of buildings, bridges, or offshore platforms. This versatility allows technicians to perform tasks in challenging environments, from inspecting and maintaining structural integrity to conducting repairs and installations.

- Minimal Impact on Surroundings: Traditional access methods often disrupt the work environment, causing damage to structures or hindering other activities. Rope access, on the other hand, has a minimal footprint, preserving the integrity of the work area and reducing the need for extensive protective measures.

- Skill Versatility: Rope access technicians are trained in various skills beyond climbing, including rigging, rescue operations, and confined space entry. This multi-skilled approach enhances their ability to perform diverse tasks efficiently and safely.

3. Versatility: A Wide Range of Applications

Rope access is not limited to a single industry; its versatility makes it suitable for a wide range of applications.

- Construction and Maintenance: Rope access is ideal for construction and maintenance tasks, including building facades, bridges, and towers. It allows workers to carry out inspections, repairs, and installations with minimal disruption to the work environment.

- Oil and Gas Industry: In the oil and gas sector, rope access is used for maintenance and inspection of offshore platforms, pipelines, and storage tanks. Its ability to reach difficult areas without the need for heavy equipment makes it indispensable in this industry.

- Renewable Energy: Rope access is increasingly used in the renewable energy sector for the maintenance of wind turbines and solar farms. Its ability to access high and remote locations efficiently supports the upkeep of these critical energy sources.

- Cultural Heritage and Restoration: Rope access is also employed in the preservation and restoration of historical buildings and monuments. It allows conservators to work safely at heights, preserving the structural and aesthetic integrity of these cultural landmarks.

4. Cost-Effectiveness: Saving Time and Money

One of the most compelling reasons to adopt rope access is its cost-effectiveness. Here’s how it stands out financially:

- Reduced Equipment Costs: Rope access eliminates the need for expensive scaffolding, cranes, or cherry pickers. The equipment required for rope access is relatively inexpensive and easy to transport, reducing overall project costs.

- Lower Labor Costs: Rope access technicians can complete tasks faster than traditional methods, reducing labor costs. Their ability to work efficiently at heights minimizes the time spent on site, leading to significant cost savings.

- Decreased Downtime: With quicker setup and dismantling times, rope access reduces project downtime. This efficiency ensures that projects are completed on schedule, avoiding costly delays and overruns.

- Minimal Environmental Impact: By reducing the need for heavy machinery and extensive scaffolding, rope access minimizes the environmental impact of projects. This sustainability aspect can also contribute to cost savings, particularly in projects with stringent environmental regulations.

Rope access is transforming the way industries approach work at heights. Its emphasis on safety, efficiency, versatility, and cost-effectiveness makes it a preferred choice for many sectors. From construction and maintenance to oil and gas, renewable energy, and cultural heritage, rope access offers a reliable and innovative solution for accessing difficult areas. As technology and techniques continue to evolve, rope access is poised to play an even more integral role in the future of industrial work, ensuring safety, enhancing productivity, and reducing costs across the board